Many 3D printed objects, or parts of objects, are used in prototyping already, but there is something that most of them lack: screw support. Or perhaps we should say they lacked, in past tense.

A team at Formlabs has created three methods for making it possible to keep 3D printed objects together using regular screws.

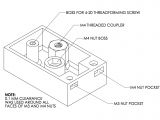

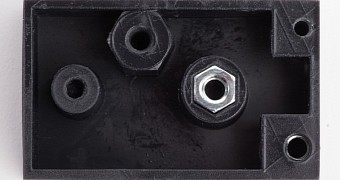

One way is to print a pocket for metal threads, which are added later with the help of a nut. The second is to print threads and chase with a tap. Finally, one can use thread-cutting screws designed for plastics to add the function.

Press-fit or heat set threaded inserts should be avoided at all costs, even if they are designed for plastic, due to the Formlabs objects being made from acrylate photopolymer resins that don't work well with those things at all.

Naturally, this advice should be heed only insofar as your 3D prints use the same materials. Then again, normal ABS or PLA plastic might not provide the same fastening.

Formlabs' techniques for adding screw threadings to 3D printed objects work best with male and female thread sizes of 1⁄4-20 or larger, although post-processing should help with smaller ones. A 0.1 mm offset gives the best engagement and wear characteristics when printing a semi-circular thread profile (on screw and nut). Here's the STL file for the most successful attempt.

14 DAY TRIAL //

14 DAY TRIAL //