Airplanes may not be something you will ever be able to build in your back yard, but that doesn't mean that you can't play with smaller miniatures. After all, they're still pretty complex since they need to be able to fly like the full-sized article.

Remote-controlled airplanes are pretty fragile, and they can be easily broken if you do anything wrong while piloting it from afar.

That's why RC planes, as toys, aren't as popular as they could be. It's not worth paying dozens or hundreds of dollars for something that may very well not survive even a day in your possession.

Sure, the inventors do their best to mitigate impact consequences, but it's not easy to do considering the price and material restrictions they are under.

Now, though, it has become possible to more easily and cheaply produce them, and you can even assemble one at home by using the following plan.

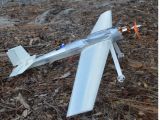

The 3D printed RC airplane

A man named Kiril Lange has published a walthrough for the creation of an RC plane on Thingiverse, one that uses 3D printing tech extensively.

Since additive manufacturing lets you make any part as long as it supports the material (in this case ABS plastic), you only need to get the electronic components and some screws.

The full part list is pretty extensive, but some things stand out like the TURNIGY Plush 30amp Speed Controller, the D2830-11 1000kv Brushless Motor, a ZIPPY Compact 2200mAh 3S 25C Lipo Pack, a Turnigy TG9e 9g / 1.5kg / 0.10sec Eco Micro Servo, and a battery charger and 4 channel transmitter/receiver. Rubber bands, glue and sandpaper have to be used quite liberally as well.

Unfortunately, this does mean that you'll need a fair bit of skill at building electromechanical contraptions. Either that, or a divine patience paired with enough money and material to replace whatever you ruin whenever you make a mistake.

The wings should be printed in ABS plastic, and if they don't turn out perfect, they should be filled with an ABS/acetone mix. The body has to be assembled first (with the basswood trimmed), then the back needs to be bolted to the front, after which the tail lattice has to be glued to the back.

After that come the servos (they have Brackets for precise insertion) and the sanding of the tail flaps (otherwise they might not rotate easily in their holes). Then the time-consuming task of attaching the wing servos, landing gear and electronics follows.

How it behaves in the air

It won't be very easy to pilot, since it's not supposed to be a beginner's plane, but it should fly well enough once you get the hang of it (and avoid destroying it of course).

14 DAY TRIAL //

14 DAY TRIAL //